Solve problems caused by damage and aging of Spindle, detects

potential errors early for repair and maintenance, helping to improve

the level Precision machining by CNC

(We repair and restore Spindle of all types of CNC from brands such as

FANUC, MITSUBISHI, PANASONIC, SIEMENS, DELTA, etc.)

□ Test Simulation CNC

- Before actual operation, we check abnormalities of equipment such as

shafts Operation, motor, Servo pack of CNC to Anticipate problems

that may occur during the process operating process.

Conduct Simulation Test to Early detection of operational problems

When abnormalities are detected, evaluate the status operates

using Error Code to determine problems and carry out repairs at

ministries the part has a problem

□ Check rotation balance of Spindle/Motor

- After repairing CNC parts, Measure RPM (revolutions per minute)

define real usually of motor / shaft / probe, etc.,

Check the eccentricity of the scale By rotating, diagnose abnormal

conditions of the motor and shaft and check the average value center

of parts such as Probe. Check the center of the parts to confirm the

mind, the sign about eccentricity or abnormality while Repair and

check for normal status after repair

□ CNC Spindle(Motor) grinding machine

- Through internal grinding device, adjustment inside evenly to

fix internal force failures due to deformation in the spindle and motor

shaft, as well as internal force problems different due to eccentricity.

By grinding positions generates friction in a special way, helping to

maintain Maintain internal balanceand stability, from there Keep the

center for rotation with high speed

□ grinding M/C to restore the appearance

- During operation, if parts superficial damage due to impact or

fall Falling leads to failure to assemble and disassemble Due to the

changed shape, we will grind and restore the appearance to enable

assembly and can be disassembled. Use magnetic centrifugal disc

automatically, we fix the product to Prevents eccentricity and

ensures smooth grinding work equally, thereby improving capabilities

restoration of the external surface

□ Remove the safety shaft Press

- This device helps eliminate internal shaft misalignment spindle safely

without Use external vacuum, At the same time, use a hydraulic press

to remove Remove internal shaft misalignment safely and effective ->

corrects errors in shaft misalignment, too This process also ensures no

variables misalignment form during removal and reinstall

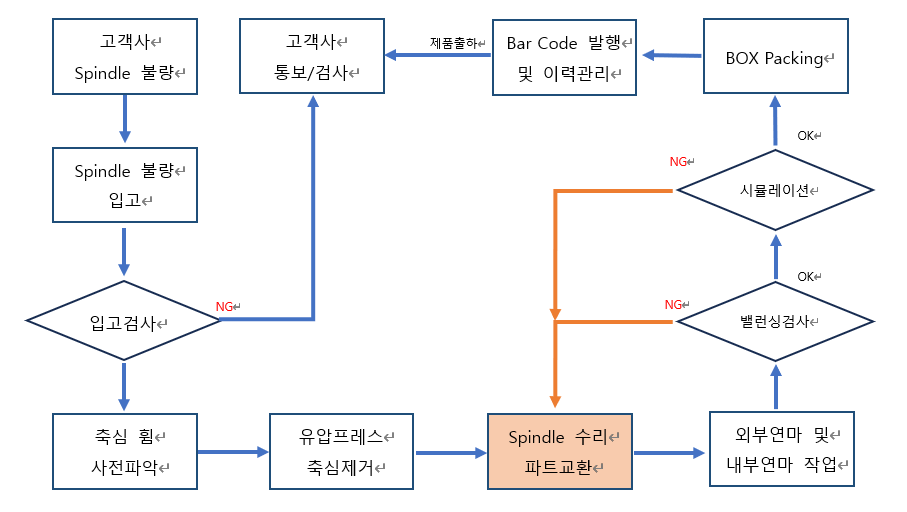

□ Repair Process

------------------------------------------------------------------------------------------

ADD : TP. Bắc Ninh, Việt Nam

Tel/ Hotline: (+84) Vietnam

0963086761

E-mail : rework.teamvn@gmail.com

wnrj7707@naver.com

kakao : kimjungho7707

zalo : 0963086761

-----------------------------------------------------------------------------------------

Repair service and sale of CNC components We specialize in repairing

CNC parts such as Probe, Spindle, Motor, Servo pack, etc.,

We also provide special parts and new parts, used parts at cheaper

prices market. Especially for Probes, we can repair and sell Probes from

major brands such as Renishaw, Hexagon, as well as other types of

Probes.We use many devices to repair, diagnose and test components

such as Spindle, Motor, Servo pack. We look forward to receiving your

interest and contact.

-----------------------------------------------------------------------------------------

Home Page : http://proberepair.modoo.at

[Probe Repair - 홈]

Probe Repair

proberepair.modoo.at

Tel/ Hotline: (+84) Vietnam

0963086761

E-mail : rework.teamvn@gmail.com

wnrj7707@naver.com

'spindle repair' 카테고리의 다른 글

| CNC 스핀들(Motor) 수리 (0) | 2024.11.05 |

|---|---|

| Sửa chữa Spindle (Motor) (0) | 2024.11.05 |